Production of a WSF spiral screen

Step 1.:

In the first step the spiral is made out of the spiral wire. This works by heating the spiral wire and then wrapping it around a spiral mandrel. This creates the spiral.

|

|

|

| spiral | spiral mandrel | spiral arises |

Step 2. :

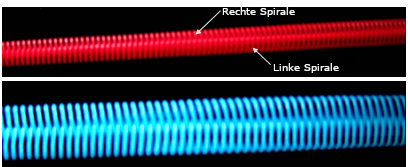

After the spiral wire is spiraled the spirals are put together.

It have to put a rigth and a left sprial alternately together.

Then the so-called pintle wire will be introduced.

Schritt 3.:

According to that the screens will be filled or at first thermofixed.

At the filling process we have two procedures.

| Filling of unfixed screens | Filling of fixed screens |

| Air permeability of 90 - 170 cfm | Air permeability of 200 - 500 cfm |

| Heat setting: | Heat setting: |

| Only one calender run |

two Kalender runs necessary |

Advantages of filling unfixed screens:

- Denser screen is possible

- Only one calender treatment is necessary

- Shortet operation time needed on the calender

- Cost savings

- Very good properties due to inclined position, like belt adhesion in a paper machine

Schritt 4.:

In step four the screens will be heat set to ensure the strength and the nuniform air permeability.

More informations about heat set can be found here.

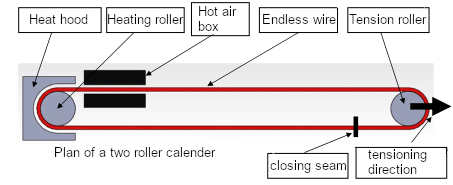

The fixing takes place in an so-called calender: