How is a spiral screen constructed?

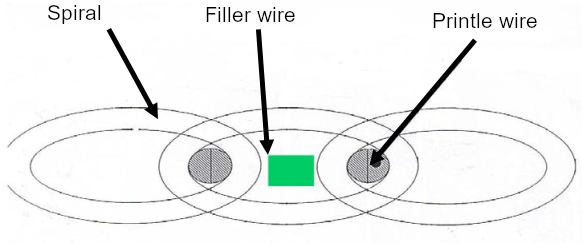

A spiral screen is constructed of a plurality of interconnected spirals. These spirals are arranged so that adjacent spiral members mesh with each other like a zipper. As a result of this intermeshing, their winding arches overlap, forming connecting channels. In these channels so-called printle wire are introduced to connect the spirals together. Always right-handed and left-handed spirals are alternately joined together. Within a spiral and between two connecting channels, another channel forms, which is called filling channel. To reduce the air permeability filler wires are inserted into these remaining cavities.

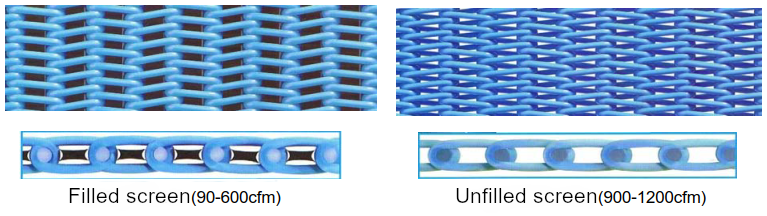

Because of this leaving the filling channels unfilled spiral sieves have a higher air permeability than filled spiral sieves. For unfilled spiral screens the air permeability is 900cfm and higher, while for filled screens the value is between 90 and 600cfm. This value depends on the size of the cored wire used. Annotation: Cfm (cubic feet per minute) is a measure for the Material throughput. cfm=1,699m³/h